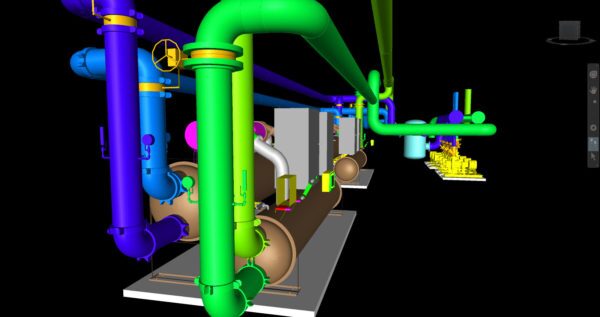

BIM has emerged as a powerful tool for coordinating Mechanical, Electrical, Plumbing, and Fire Protection with Architectural and Structural designs. It is extremely valuable to resolve any conflicts prior to having trade labor on site. At Atomatic, we not only value the coordination aspects of BIM, but concentrate on the INFORMATION embedded within the model. When the model is complete, we can get material lists and labor estimates for both piping and ductwork. This is extremely helpful when managing our field labor. Additionally, we can cut sheet metal material in our shop for duct fabrication directly from the model with the click of a mouse. For large piping projects, we can derive spool sheets for pipe fabrication direct from the model. This allows us to perform a high percentage of the welds in a controlled environment, off-site. When there is less welding on site, there is also less material storage, and toxic welding fumes to manage.